|

This page encompasses all of the small projects I need to complete the

exterior of the cabin top, including, in no chronological or project based order:

Improving the Dorade

Boxes

The

Bristol dorade boxes are molded into the cabin top and are a distinctive and

identifying feature of Bristols. The trouble with the dorades is there is a

gap between the molded cabin top and the bottom layer of glass that

sandwiches the balsa core. That gap holds water, mold, mildew, dirt and God

knows what else. Additionally, the box itself is not as large as I would

like. SO as a part of this refit I will improve them by,

-

Filling in the "gap between the top layer of the cabin top and the bottom

layer so that no water can be trapped,

-

Covering with teak like a proper dorade should be, and

-

Strengthening the whole box so it can stand up to any seas.

I will

build a third dorade at the bow to ventilate the anchor locker.

If you

ever wondered what the inside of your molded dorades looked like, take a

look at these shots:

I

cut the top off the two dorades with a sawsall. The drains for the cowl side

of the dorade should be at the aft corners, not as they are. I

cut the top off the two dorades with a sawsall. The drains for the cowl side

of the dorade should be at the aft corners, not as they are.

As I look at the dorades closer I

discover this:

The dorade boxes

on the Bristol were made by molding the outer fiberglass skin in the shape

of the box, eliminating the core between the out and inner skins and

drilling a 3” hole in the inner skin into the cabin. The problem with this

design is that the base of the box is below the outer surface of the outer

skin, leaving a depression for water to collect and stand. To do it right, I

will need to cut off all of the structure of the box, fill the depression

with thickened epoxy and the build the box on top of the outer skin, like

a proper dorade box should be.

The

bigger problem with the dorades is the "gap" that you can see in this

picture. It goes about 3/4 of an inch up under the deck. The gap exists

around the entire box. The

bigger problem with the dorades is the "gap" that you can see in this

picture. It goes about 3/4 of an inch up under the deck. The gap exists

around the entire box.

I

filled it by first wetting it out with unthickened epoxy, I

filled it by first wetting it out with unthickened epoxy,

then

packing some thickened epoxy into a caulking tube and running a bead all the

way around. then

packing some thickened epoxy into a caulking tube and running a bead all the

way around.

When

the epoxy cures I will sand the insides smooth, paint them out and begin

covering the outside with teak. Stay tuned... When

the epoxy cures I will sand the insides smooth, paint them out and begin

covering the outside with teak. Stay tuned...

Here

I have started to cut and shape the teak to enclose the dorades. It is a

plethora of angles. Here

I have started to cut and shape the teak to enclose the dorades. It is a

plethora of angles.

After

the four sides are cut to all the After

the four sides are cut to all the

needed

angles I clamp them in place with some plastic kitchen wrap under the

corners. The plastic allows me to glue the sides clamped in place over the

fiberglass needed

angles I clamp them in place with some plastic kitchen wrap under the

corners. The plastic allows me to glue the sides clamped in place over the

fiberglass

sides

of the dorade, and remove it when the epoxy dries. Then, I trimmed the sides

with a Japanese saw, shaped it with my small belt sander and applied a first

coat of epoxy thinned with acetone as a sealer. Before I can glue the dorade

in place and add the top I need to recut the 3" vent holes in the cabin top.

In preparation I glued in place two large pieces of 1/4" plywood. sides

of the dorade, and remove it when the epoxy dries. Then, I trimmed the sides

with a Japanese saw, shaped it with my small belt sander and applied a first

coat of epoxy thinned with acetone as a sealer. Before I can glue the dorade

in place and add the top I need to recut the 3" vent holes in the cabin top.

In preparation I glued in place two large pieces of 1/4" plywood.

Here

is the dorade frame with its first coat of sealer. Here

is the dorade frame with its first coat of sealer.

After building both dorade fames to fit

the existing fiberglass boxes, I finished a few small steps prior to fitting

the tops in place.

I glued 1/4 plywood in place under each

vent hole. The plywood will allow me to screw into place a 3" brass deck

plate so I can seal the vents from inside the boat.

I recut the 3" hole using a 3-3/8" hole

saw and sealed the edges of the fiberglass and plywood.

I glued a PVC stand pipe over the hole

in each dorade box.

And

I glued nylon screening to the top of the stand pipe. When Olin Stephens

invented the dorade box he said firmly that screening was not necessary to

keep out mosquitoes because they prevented light from showing outside and so

the small bugs would not be attracted. I have glued screening to the three

dorades because I wish to keep out larger pests, especially roaches. And

I glued nylon screening to the top of the stand pipe. When Olin Stephens

invented the dorade box he said firmly that screening was not necessary to

keep out mosquitoes because they prevented light from showing outside and so

the small bugs would not be attracted. I have glued screening to the three

dorades because I wish to keep out larger pests, especially roaches.

Once

the glue for the screens dried, I bored new Once

the glue for the screens dried, I bored new

drain

holes in each of the fiberglass boxes and in each teak box. Two holes, on

the aft face of each box, unlike what Bristol had built, allows the boxes to drain on either tack. drain

holes in each of the fiberglass boxes and in each teak box. Two holes, on

the aft face of each box, unlike what Bristol had built, allows the boxes to drain on either tack.

I

prepared the top by first checking to see that each box was the same height

and level to the leveled hull. I

prepared the top by first checking to see that each box was the same height

and level to the leveled hull.

They

are close enough for my tastes. Then I turned over the port box and set it

down into a They

are close enough for my tastes. Then I turned over the port box and set it

down into a thick fillet of thickened epoxy. Once it was aligned and clamped, I added 9

oz fiberglass tape around all the seams.

thick fillet of thickened epoxy. Once it was aligned and clamped, I added 9

oz fiberglass tape around all the seams.

I spent a total of an hour sanding and

shaping the top to the already shaped box of the starboard dorade. I used my

Festool Rotex 150 which made amazing short and easy work of it. Some

pictures follow.

And here is the port dorade shaped and

ready to be mounted:

Here

I have sanded them with 220 wet or dry and applied the first of three coats

of epoxy. I wet sanded the first coat with 320 grade abrasive and the

applied a second coat of epoxy. Here

I have sanded them with 220 wet or dry and applied the first of three coats

of epoxy. I wet sanded the first coat with 320 grade abrasive and the

applied a second coat of epoxy.

With two coats of epoxy on the two

dorade boxes I test positioned the dorades and the

dorade

guards. The guards function as a brace for my butt when I am working at the

mast, as a means of keeping flogging lines from wrapping around the dorade

cowls, and as a guard to protect the cowls from the mainsheet, dorade

guards. The guards function as a brace for my butt when I am working at the

mast, as a means of keeping flogging lines from wrapping around the dorade

cowls, and as a guard to protect the cowls from the mainsheet,

which

runs down from the boom to a turning block on the mast step. The photo on

the right shows the angle of the mainsheet with the boom extended. the sheet

will run free without chaffing the starboard guard. which

runs down from the boom to a turning block on the mast step. The photo on

the right shows the angle of the mainsheet with the boom extended. the sheet

will run free without chaffing the starboard guard.

I installed temporarily the port dorade

box with the cowl just to get an idea of how everything will look. Here are

a few shots.

Here

is one of the dorades after applying a second coat of System Three LPU clear

gloss. Here

is one of the dorades after applying a second coat of System Three LPU clear

gloss.

It

was applied over three coats of epoxy that I wet sanded to 320 grade. The S3

gloss is dry in this photo but hasn't yet been sanded. It

was applied over three coats of epoxy that I wet sanded to 320 grade. The S3

gloss is dry in this photo but hasn't yet been sanded.

The next step in improving the dorades

is to mount the dorade guards.

Previously

I

overbored all the 18 mounting holes. Now I positioned each guard back in

place and carefully drilled the holes and taped each of them. I

overbored all the 18 mounting holes. Now I positioned each guard back in

place and carefully drilled the holes and taped each of them.

I

used my portable drill press rig as I always do to ensure that I drilled

perpendicular to the surface of the cabin top. I

used my portable drill press rig as I always do to ensure that I drilled

perpendicular to the surface of the cabin top.

I

used a 10-24 drill and tap set for them guard bases. Once all the mounting

holes were tapped and dry fitted the guards. Then, I removed the guards,

removed the bases and epoxied the bases to the guard tubes. I

used a 10-24 drill and tap set for them guard bases. Once all the mounting

holes were tapped and dry fitted the guards. Then, I removed the guards,

removed the bases and epoxied the bases to the guard tubes.

These

guards are a life saving feature of the improvements to my boat I will be

trusting my life to them when I am offshore, so i will epoxy the tubes to

the bases and then drill the bases and thru-bolt them as well. These

guards are a life saving feature of the improvements to my boat I will be

trusting my life to them when I am offshore, so i will epoxy the tubes to

the bases and then drill the bases and thru-bolt them as well.

Here

both guards are mounted and glued and I'm waiting for everything to dry.

Excuse all the clutter, After all the holes were drilled and tapped for the

guards, as well as for all the other holes in the deck and cabin top, Here

both guards are mounted and glued and I'm waiting for everything to dry.

Excuse all the clutter, After all the holes were drilled and tapped for the

guards, as well as for all the other holes in the deck and cabin top, I bought some cheap screws at Home Depot and installed them to keep paint

from running down into the holes.

I bought some cheap screws at Home Depot and installed them to keep paint

from running down into the holes.

Remove the old

mainsheet winch base

Today, I began removing the mainsheet

winch base on the port

side

of the cabin top. I will move the location of that winch aft and the winch

base only interferes. I began sanding it down with a very aggressive belt

sander, but my brother suggested using my Fein Multimaster with the flush

cutting blade. Wow, does that thing cut. We had the base removed in a matter

of minutes. I filled with thickened epoxy and will sand flush with the

surrounding cabin. side

of the cabin top. I will move the location of that winch aft and the winch

base only interferes. I began sanding it down with a very aggressive belt

sander, but my brother suggested using my Fein Multimaster with the flush

cutting blade. Wow, does that thing cut. We had the base removed in a matter

of minutes. I filled with thickened epoxy and will sand flush with the

surrounding cabin.

Next

I over bored the screw holes when I will bolt the seahood to the cabin. The

screws set the proper angle for screwing up into the seahood, which has

already been overbored and filled with thickened epoxy, I poured thickened

epoxy around the screws and when the mix kicked I backed out the screws,

leaving the holes in the hardened glue. The holes will act as guides for my

tap later--I will tap and attach the seahood with 1/4"x2" machine screws

when everything is sanded and ready for paint. Next

I over bored the screw holes when I will bolt the seahood to the cabin. The

screws set the proper angle for screwing up into the seahood, which has

already been overbored and filled with thickened epoxy, I poured thickened

epoxy around the screws and when the mix kicked I backed out the screws,

leaving the holes in the hardened glue. The holes will act as guides for my

tap later--I will tap and attach the seahood with 1/4"x2" machine screws

when everything is sanded and ready for paint.

By the way, as a comparison to

the photo above showing the old dirty nonskid... I

recently acquired a

Festool Rotex 150 orbital sander and used it for the first time

on the cabin I

recently acquired a

Festool Rotex 150 orbital sander and used it for the first time

on the cabin

doghouse

nonskid. Even with the wrong abrasive paper for fiberglass, the tool

removed the nonskid and old Awlgrip paint in a matter of minutes

down to a finish the equivalent of 400 grit wet sanding. doghouse

nonskid. Even with the wrong abrasive paper for fiberglass, the tool

removed the nonskid and old Awlgrip paint in a matter of minutes

down to a finish the equivalent of 400 grit wet sanding.

Painting the Companionway Hatch

Today

I sprayed the companionway sliding hatch. The temperature was only in the

mid 60's, but System Three paint seems to thrive in cold weather: it flowed

very well. The base coats of Orcas White dried in about 20 minutes. It was

thinned 25 percent with water. Previously I had sprayed the hatch with

System Three WR-155 epoxy primer, and sanded lightly with 220 wet or dry. Today

I sprayed the companionway sliding hatch. The temperature was only in the

mid 60's, but System Three paint seems to thrive in cold weather: it flowed

very well. The base coats of Orcas White dried in about 20 minutes. It was

thinned 25 percent with water. Previously I had sprayed the hatch with

System Three WR-155 epoxy primer, and sanded lightly with 220 wet or dry.

After

an hour of drying, I mixed 4 ounces of Gloss Clear crosslinked and sprayed

it over the base coat. Again, the clear flowed very well and dried to the

touch in an hour. Once the crosslinked coats have a week to dry and harden

completely I will mount the sliding hatch and the seahood over it and begin

building the dodger coaming down along each side of the doghouse. After

an hour of drying, I mixed 4 ounces of Gloss Clear crosslinked and sprayed

it over the base coat. Again, the clear flowed very well and dried to the

touch in an hour. Once the crosslinked coats have a week to dry and harden

completely I will mount the sliding hatch and the seahood over it and begin

building the dodger coaming down along each side of the doghouse.

Handrails

While waiting for the companionway

hatch to dry, I positioned

and

drill holes in the dog house for the stainless handrails. I then over bored

each hole with a 3/4" spade bit thru the top layer of glass and the balsa

core, but not cutting thru the bottom layer of fiberglass. Then I used a

small screwdriver to dig balsa out wider than the bored hole. and

drill holes in the dog house for the stainless handrails. I then over bored

each hole with a 3/4" spade bit thru the top layer of glass and the balsa

core, but not cutting thru the bottom layer of fiberglass. Then I used a

small screwdriver to dig balsa out wider than the bored hole.

Taping

over the inside of the hole prevents any drips. The adhesive on the tape

acts as a mold release and the glue will not stick to it. Taping

over the inside of the hole prevents any drips. The adhesive on the tape

acts as a mold release and the glue will not stick to it.

Here

are some of the bored holes. Here

are some of the bored holes.

Here they are filled and ready for

first sanding.

once

sanded completely smooth I will redrill the 1/4" holes to accept the

threaded studs of the handrails. once

sanded completely smooth I will redrill the 1/4" holes to accept the

threaded studs of the handrails.

Here a handrail is temporarily

mounted.

The

forward handrail stud. The

forward handrail stud.

Building a Dodger Splash Coaming

The idea

of the coaming is to provide a lip to screw snaps into to attach the bottom

edge of a dodger and offer more protection from any spray or seas. The

coaming will extend the aft edge of the

seahood down each side of the cabin top to act as an attachment point for

the dodger. Now that I have the seahood finished and the companionway hatch

painted, they can be installed and accurate measurements taken for the

coaming.

I began by

marking the outline on the cabin: each side extends to port and starboard,

then takes an accurate angle aft to intersect with the cabinsides aft of the

rear portlight and in line with the forward cockpit coaming attachment.

I used basswood and roughed out the shape on my trusty 12" band saw. It took

three attempts before I finally got what I wanted. The basswood will be

encapsulated in epoxy and i will add a layer or two of cloth to protect it.

Here

you can see I have marked out on the cabin top the outline of the coaming. Here

you can see I have marked out on the cabin top the outline of the coaming.

The

port coaming roughed and positioned for fit. The

port coaming roughed and positioned for fit.

The

starboard coaming. I've started to shape it with a rasp. The

starboard coaming. I've started to shape it with a rasp.

Here

I am starting to shape the diagonal side rail. It has about as many angles

as you can imagine. I take off the curves with a compass and use my band saw

to do the cutting. Here

I am starting to shape the diagonal side rail. It has about as many angles

as you can imagine. I take off the curves with a compass and use my band saw

to do the cutting.

Here

is the same diagonal, cut to fit, temporarily screwed down and set in

thickened epoxy. Here

is the same diagonal, cut to fit, temporarily screwed down and set in

thickened epoxy.

Here's

the starboard side looking forward. When the epoxy is tack free, I'll add a

layer of epoxy in microballons to begin fairing it. Here's

the starboard side looking forward. When the epoxy is tack free, I'll add a

layer of epoxy in microballons to begin fairing it.

Here

is the starboard coaming faired and ready for paint. Here

is the starboard coaming faired and ready for paint.

Here

is the port dodger coaming roughly shaped and bedded in thickened epoxy. Here

is the port dodger coaming roughly shaped and bedded in thickened epoxy.

Another

angle for the port coaming. Another

angle for the port coaming.

Today

I added the first of two layers of 6oz fiberglass to the coamings. Today

I added the first of two layers of 6oz fiberglass to the coamings. When

it hardened I trimmed off the scrap with a sharp knife, sanded the weave

down smooth and added a second layer of cloth. I will sand that smooth and

then paint the coamings with System Three epoxy primer. Then, all that is

left is to drill the holes for the lines that will feed the rope clutches

and the two winches. When

it hardened I trimmed off the scrap with a sharp knife, sanded the weave

down smooth and added a second layer of cloth. I will sand that smooth and

then paint the coamings with System Three epoxy primer. Then, all that is

left is to drill the holes for the lines that will feed the rope clutches

and the two winches.

Here are

the coamings primed with the first coat of System Three WR-155 water-based

epoxy primer.

Here

I have bored the holes for the lines that run aft to sheet stoppers and the

port winch: the windward traveller car haul, the outhaul and the mainsheet.

I will add fairleads to the holes glued in thickened epoxy, then mount the

sheet stoppers and the winch, a Lewmar two-speed #16. Here

I have bored the holes for the lines that run aft to sheet stoppers and the

port winch: the windward traveller car haul, the outhaul and the mainsheet.

I will add fairleads to the holes glued in thickened epoxy, then mount the

sheet stoppers and the winch, a Lewmar two-speed #16.

Installing a Traveller Riser

Today I took off the measurements

needed to order and have built stainless steel risers to support the midboom

traveller. I am ordering these from

Garhauer

Marine. They build them to your custom specifications

and

Garhauer does beautiful work at a very reasonable price. Here are the

measurements: and

Garhauer does beautiful work at a very reasonable price. Here are the

measurements:

This is

what

the risers look like from the Garhauer catalog: what

the risers look like from the Garhauer catalog:

I ordered

the traveller risers from Garhauer at the Strictly Sail Miami boat show

yesterday. They should be here in a week.

The

risers arrived this afternoon and I thought I would share them with you.

These are the smaller of two models, designated UR1. They are

extremely beefy. They are custom made to my measurements, from a full 1/4"

stainless plate, with perfect welds and polished like chrome. They regularly

cost $170.00 for the pair in the Garhauer catalog. I got them for $150.00

including shipping at the Miami Strictly Sail boat show. It took a little

more than a month to get them. The

risers arrived this afternoon and I thought I would share them with you.

These are the smaller of two models, designated UR1. They are

extremely beefy. They are custom made to my measurements, from a full 1/4"

stainless plate, with perfect welds and polished like chrome. They regularly

cost $170.00 for the pair in the Garhauer catalog. I got them for $150.00

including shipping at the Miami Strictly Sail boat show. It took a little

more than a month to get them.

Each

riser has a very classy Garhauer logo on it. You can judge the polished

stainless by the reflection here. Each

riser has a very classy Garhauer logo on it. You can judge the polished

stainless by the reflection here.

Here

is the basic shape from the side view. The base pivots to account for the

curve of the cabin top. The horizontal plate is drilled for attaching the

traveller. You can use Garhauer's traveller if you want to buy their

traveller blocks. In my case, I already have a Harken Midrange traveller

system so I will attach it to these risers. Here

is the basic shape from the side view. The base pivots to account for the

curve of the cabin top. The horizontal plate is drilled for attaching the

traveller. You can use Garhauer's traveller if you want to buy their

traveller blocks. In my case, I already have a Harken Midrange traveller

system so I will attach it to these risers.

Here's

the underside of the unit. As perfectly finished in brushed stainless as the

outside is polished. These are just gorgeous units. the workmanship in

Garhauer's products is first rate and their prices are really amazing. Here's

the underside of the unit. As perfectly finished in brushed stainless as the

outside is polished. These are just gorgeous units. the workmanship in

Garhauer's products is first rate and their prices are really amazing.

Here

is a close up of on of the welds on the underside where they don't show. I

expected less than perfect welds here--it doesn't matter right? Wrong. The

welds are damn near perfect, as much as they are on the outside. Here

is a close up of on of the welds on the underside where they don't show. I

expected less than perfect welds here--it doesn't matter right? Wrong. The

welds are damn near perfect, as much as they are on the outside.

Next,

I mocked up the traveller clamped to the risers to get an idea as to how

close my measurements were. I took a straight piece of trim and clamped it

to both risers. Then adjusted each riser so it was 7 inches in from the edge

of the cabinside. Next,

I mocked up the traveller clamped to the risers to get an idea as to how

close my measurements were. I took a straight piece of trim and clamped it

to both risers. Then adjusted each riser so it was 7 inches in from the edge

of the cabinside.

The

results are exactly what I wanted. The bottom of the riser will be about

1/3" above the seahood. The

results are exactly what I wanted. The bottom of the riser will be about

1/3" above the seahood.

Here

is the port side riser close to its final position. Here

is the port side riser close to its final position.

Here

is the starboard side riser in position. Here

is the starboard side riser in position.

Since the cabin top is curved and the

attachment base of the risers is flat I felt I needed a flat bearing

surface. A midboom traveller must handle enormous forces: just think of a

jibe in heavy weather and you begin to understand the strains it must

absorb. I also believe midboom traveller risers are a common source of leaks

into the cored cabin top--they usually are not mounted correctly and become a

major source of leaks. So these risers will be mounted in a way that leaks

are impossible. The outer cabin surface and the inside cabin surface will be

flat so that the bearing surface of the mount and its associated backing

plate will have a full flat surface to bear against. Furthermore, the bolt

holes for the two riser brackets will be tapped to prevent any movement and

any egress of water.

The outside

riser base and the backing plate on the inside will be sandwiched between:

For

the flat exterior pads, I cut some 1/4" fiberglass stock I have from McMaster Carr to

the shape of the backing plate, faired the edges, and mounted it to the

cabin top in thickened epoxy. For

the flat exterior pads, I cut some 1/4" fiberglass stock I have from McMaster Carr to

the shape of the backing plate, faired the edges, and mounted it to the

cabin top in thickened epoxy.

On

the inside of the cabin I fashioned two 1/4" pieces of plywood and mounted

them in thickened epoxy. I did not tighten down the temporary attachment

screws so the pads would assume the curve of the cabin top; I purposely left

them flat. They will act as a spacer for the Formica overhead cabin panels to lie

against so that torque of the nuts on the backing plate do not stress or

crack the Formica. On

the inside of the cabin I fashioned two 1/4" pieces of plywood and mounted

them in thickened epoxy. I did not tighten down the temporary attachment

screws so the pads would assume the curve of the cabin top; I purposely left

them flat. They will act as a spacer for the Formica overhead cabin panels to lie

against so that torque of the nuts on the backing plate do not stress or

crack the Formica.

Then

I overbored the mounting holes for the riser brackets and filled them with

thickened epoxy. The mounting brackets for the Garhauer risers are drilled

for 1/4" flathead bolts. Probably that is more than sufficient, but I

drilled out the holes to the next size, 5/16". The flatheads will stand a

little proud but I like the extra beef of the significantly larger bolts. Then

I overbored the mounting holes for the riser brackets and filled them with

thickened epoxy. The mounting brackets for the Garhauer risers are drilled

for 1/4" flathead bolts. Probably that is more than sufficient, but I

drilled out the holes to the next size, 5/16". The flatheads will stand a

little proud but I like the extra beef of the significantly larger bolts.

I

ordered the new Harken traveller bar and received it today. It is very

stout, uses a continuous running bolt head slot on the underside and comes

with 8 I

ordered the new Harken traveller bar and received it today. It is very

stout, uses a continuous running bolt head slot on the underside and comes

with 8

stainless

steel bolt head plates to fit into the slot. I ordered all stainless 316

hardware to attach the risers to the traveller. I used acorn nuts to create

a finished look to the underside and used blue Lok-Tite to keep everything

tight. In order to prevent any corrosion between the stainless risers

and stainless mounting bolts and the aluminum traveller, I coated the bolt

heads and the head plates that ride in the slot liberally with

LanoCote and also the underside of the traveller that touches the

risers. stainless

steel bolt head plates to fit into the slot. I ordered all stainless 316

hardware to attach the risers to the traveller. I used acorn nuts to create

a finished look to the underside and used blue Lok-Tite to keep everything

tight. In order to prevent any corrosion between the stainless risers

and stainless mounting bolts and the aluminum traveller, I coated the bolt

heads and the head plates that ride in the slot liberally with

LanoCote and also the underside of the traveller that touches the

risers.

Here

is the port riser positioned on the mounting pad. Here

is the port riser positioned on the mounting pad.

To

ensure I am drilling the mounting holes for the riser brackets square to the

mounting pads, I use a portable drill press jig I bought at Home Depot. I

mark the first hole, drill it, tap it, then mount the bracket and use it as

the template for the second hole. Remove the bracket, drill and tap the

second hole, remount the bracket for the third hole, etc. To

ensure I am drilling the mounting holes for the riser brackets square to the

mounting pads, I use a portable drill press jig I bought at Home Depot. I

mark the first hole, drill it, tap it, then mount the bracket and use it as

the template for the second hole. Remove the bracket, drill and tap the

second hole, remount the bracket for the third hole, etc.

Here,

all the holes are taped and ready for the bracket. Here,

all the holes are taped and ready for the bracket.

Here

is the bracket mounted in place with the 5/16 x 2-1/3 inch machine screws. Here

is the bracket mounted in place with the 5/16 x 2-1/3 inch machine screws.

You

can see the screws protruding here. When the cabin is finished there will be

a sheet of Formica over the plywood base. You

can see the screws protruding here. When the cabin is finished there will be

a sheet of Formica over the plywood base.

Everything

lined up very nicely. Here the backing plate from Garhauer is on just for

fit and the cap nuts are tightened down. Everything

lined up very nicely. Here the backing plate from Garhauer is on just for

fit and the cap nuts are tightened down.

After positioning the traveller in

place, I used a 3/8" line to determine the exact positions for the

traveller car control line turning blocks. The line must exit to the

side of the traveller, down to a turning block to get the line parallel to

the cabin top, and then another turning block to turn the line 90 degrees to

lead thru the dodger coaming and eventually a winch. Here I have overboard

the holes for one of the four turning blocks--two per side. The Garhauer

turning blocks have the heads of rivets on the bottom so they do not sit

flush to the cabin, so I am going to build a base of epoxy for the to sit

on.

Here

you can see the rivets (I have wrapped the turning Here

you can see the rivets (I have wrapped the turning

block

in plastic wrap to keep it from sticking to the epoxy. Then I marked the

perimeter of the holes so I can find them after the epoxy base is finished.

Next, I mixed up a block

in plastic wrap to keep it from sticking to the epoxy. Then I marked the

perimeter of the holes so I can find them after the epoxy base is finished.

Next, I mixed up a

very

thick batch of epoxy with 404 high density adhesive very

thick batch of epoxy with 404 high density adhesive

filler

and buttered up the base of the turning block. I pressed the block down

exactly where I wanted it so the epoxy spluged out. I used the sharp edge of

the West stirring stick to clean up the excess epoxy and taped the turning

block in place. filler

and buttered up the base of the turning block. I pressed the block down

exactly where I wanted it so the epoxy spluged out. I used the sharp edge of

the West stirring stick to clean up the excess epoxy and taped the turning

block in place. Tomorrow I will removed the blocks and drill and tap the holes for

fasteners.

Tomorrow I will removed the blocks and drill and tap the holes for

fasteners.

Installing the new Man Ship

Forward Hatch

My Hatch Arrives

Here are some pics of the custom-made

trapezoid

Bristol 29 hatch. If you are like me and dreamed of a weather proof,

sea-proof hatch, this is it folks. I can not begin to say enough good things

about Mariner's Hardware and Man Ship. take a look:

It

is difficult to photograph, but this is the hatch right side up, still

wearing the UV protective film over the acrylic light. It

is difficult to photograph, but this is the hatch right side up, still

wearing the UV protective film over the acrylic light.

You

can see the quality of the stainless (316), the welds and the polishing in

this shot. Here is one of the hinges with my Canon S-50 perfectly reflected.

The stainless looks like high quality chrome, only smoother and more

reflective. You

can see the quality of the stainless (316), the welds and the polishing in

this shot. Here is one of the hinges with my Canon S-50 perfectly reflected.

The stainless looks like high quality chrome, only smoother and more

reflective.

Here

is the underside of the hatch. Notice the caulking detent built in to the

inner edge of the trim, the handles and the general high quality of the

workmanship. Here

is the underside of the hatch. Notice the caulking detent built in to the

inner edge of the trim, the handles and the general high quality of the

workmanship.

The

Man Ship logo on the underside of the acrylic light. CE indicates a similar

European Union standard of quality to ISO9000. The

Man Ship logo on the underside of the acrylic light. CE indicates a similar

European Union standard of quality to ISO9000.

Installing the Forward Hatch

Today I prepared the raised forward

hatch combing to received the new hatch. The Bristol's combing is curved and

uses a curved fiberglass hatch that matches the crown of the cabin top.

The

crown needed to be taken out of the combing in order to fit the new hatch. I

could have used a variety of tools--a The

crown needed to be taken out of the combing in order to fit the new hatch. I

could have used a variety of tools--a

grinder

was suggested by my brother and a Sawsall comes readily to mind, but I wound

up using my trusty belt sander. It took about and hour and was very

controllable. I kept a level handy to act as a straight edge. I will have to

fill the weather stripping groove and bull nose the outboard edges of the

combing, but it will work just fine for the new hatch. Stay tuned for the

hatch installation next weekend. grinder

was suggested by my brother and a Sawsall comes readily to mind, but I wound

up using my trusty belt sander. It took about and hour and was very

controllable. I kept a level handy to act as a straight edge. I will have to

fill the weather stripping groove and bull nose the outboard edges of the

combing, but it will work just fine for the new hatch. Stay tuned for the

hatch installation next weekend.

Today I continued modifying the forward

hatch combing to receive the new hatch. After leveling it as best I could

with the belt sander, I dry fitted the hatch and marked low spots.

I

puttied up the edges where I marked with thickened epoxy and sanded again.

Then I

puttied up the edges where I marked with thickened epoxy and sanded again.

Then

I

took the belt sander to the sharp corners, rounding them and bullnosing the

exterior edge of the combing. The sander cut through into some voids in the

glass, which I later filled and faired with epoxy. Here is the hatch dry

fitted. I

took the belt sander to the sharp corners, rounding them and bullnosing the

exterior edge of the combing. The sander cut through into some voids in the

glass, which I later filled and faired with epoxy. Here is the hatch dry

fitted.

The

combings are close to finished. They will received a coat of System Three

epoxy primer. Then I will screw down the hatch but not bed it yet, as I want

to remove it and the new ports when I paint the deck and cabin trunk. The

combings are close to finished. They will received a coat of System Three

epoxy primer. Then I will screw down the hatch but not bed it yet, as I want

to remove it and the new ports when I paint the deck and cabin trunk.

I

also ground flat the famous Bristol hatch lips where the yard bonded the

cabin liner to the openings in the deck and cabin. It's always sort of an ugly,

rough way to finish the joints and is common to most Bristol's. Since I

am going to finish the inside of the hatch opening with cherry trim, it needs

to be flat (like it should have been 40 years ago). I

also ground flat the famous Bristol hatch lips where the yard bonded the

cabin liner to the openings in the deck and cabin. It's always sort of an ugly,

rough way to finish the joints and is common to most Bristol's. Since I

am going to finish the inside of the hatch opening with cherry trim, it needs

to be flat (like it should have been 40 years ago).

Today I did a number of small steps

toward getting the hatch installed.

Overbored all the mounting holes for

the hatch and filled with thickened epoxy.

Redrilled for the #12 x 1-1/2 in 316

stainless self tapping screws I ordered from McMaster.

Began dressing the inside vertical

sides of the hatch coaming with cherry.

Here are a couple of pics:

s |

Here, the

mounting holes have been oveboard, filled and redrilled for the #12

screws. The holes have also been chamfered. |

|

I painted the

backs of the cherry planks and the insides of the coamings with

unthickened epoxy, then added filler to make a peanut butter

consistency and buttered the backs of each board. |

Mounting Hardware on the

Cabin and Deck

this is the beginning of a description

of mounting hardware on the cabin and deck. The first being a

1. Spinlock turning block

Here

you can see that I have overbored for a new Spinlock turning block that will

accept the mainsheet and the outhaul and route them back to the port side

cabin winch. I cannot stress the importance of overborning a cored cabin top

or deck. It is so easy there is no reason not to do it. The Spinlock

takes a 1/4" bolt, so I overbored with a 5/8" hole. I will redrill it

through now solid epoxy and it will never be stressed, or leak water into

the balsa core. It is 50 year solution and one that you should always do. Here

you can see that I have overbored for a new Spinlock turning block that will

accept the mainsheet and the outhaul and route them back to the port side

cabin winch. I cannot stress the importance of overborning a cored cabin top

or deck. It is so easy there is no reason not to do it. The Spinlock

takes a 1/4" bolt, so I overbored with a 5/8" hole. I will redrill it

through now solid epoxy and it will never be stressed, or leak water into

the balsa core. It is 50 year solution and one that you should always do.

Here's how

to keep water out of your coring:

Fill

with thickened epoxy. Fill

with thickened epoxy.

Drill

for the size fastener, in this case 1/4" holes. Drill

for the size fastener, in this case 1/4" holes.

Use

a chamfered bore, like this to create a bevel edge to the hole. Use

a chamfered bore, like this to create a bevel edge to the hole.

Like

this. The bevel will hold a nice bead of caulking that won't be squeezed out

when you tighten the fastener. Like

this. The bevel will hold a nice bead of caulking that won't be squeezed out

when you tighten the fastener.

Holes

ready for the fasteners.. Holes

ready for the fasteners..

Here's

the turning block mounted temporarily. Here's

the turning block mounted temporarily.

The

bolts go through, washers and nuts with Lok-Tite added and the bolts cut off

flush with the bottom of the nut. The whole assembly is less than 1/4" thick

so it doesn't interfere with my overhead panels. Do this

with every fastener thru your cabin and deck and you will never never have a

problem with core saturation. The

bolts go through, washers and nuts with Lok-Tite added and the bolts cut off

flush with the bottom of the nut. The whole assembly is less than 1/4" thick

so it doesn't interfere with my overhead panels. Do this

with every fastener thru your cabin and deck and you will never never have a

problem with core saturation.

Cabintop Lewmar Winches

I

am mounting a Spinlock triple clutch and a Lewmar #16 two speed winch on the

port cabin top. The winch serves the mainsheet, the outhaul and the portside

traveller car haul. Here you can see I have overbored the mounting holes for

the rope clutches and the winch base. These will be filled and re-drilled

like the description above. The winch will be tilted aft 10 degrees and I

will make a tilted base out of thickened epoxy for it. I will install a

single clutch and a Lewmar #7 on the starboard to handle the starboard side

traveller car haul. I

am mounting a Spinlock triple clutch and a Lewmar #16 two speed winch on the

port cabin top. The winch serves the mainsheet, the outhaul and the portside

traveller car haul. Here you can see I have overbored the mounting holes for

the rope clutches and the winch base. These will be filled and re-drilled

like the description above. The winch will be tilted aft 10 degrees and I

will make a tilted base out of thickened epoxy for it. I will install a

single clutch and a Lewmar #7 on the starboard to handle the starboard side

traveller car haul.

Here

is the portside holes filled with the first filling and sanded smooth. Here

is the portside holes filled with the first filling and sanded smooth.

Here

is the starboard side with the first filling. Here

is the starboard side with the first filling.

So I want to tilt the port winch ab out

10 degrees to prevent overrides. If you read the West System manual, the

instructions are very detailed: it's easy and quick to do. The most

important step is to cover your winch base with some kind of release

agent--I use kitchen plastic wrap. The use a couple of scrapes of wood to

raise the forward edge, or the edge you wish to tilt. Mark everything with a

pencil so you can align it later--also an important step. out

10 degrees to prevent overrides. If you read the West System manual, the

instructions are very detailed: it's easy and quick to do. The most

important step is to cover your winch base with some kind of release

agent--I use kitchen plastic wrap. The use a couple of scrapes of wood to

raise the forward edge, or the edge you wish to tilt. Mark everything with a

pencil so you can align it later--also an important step.

I

mixed up a 2 or 3 squirt mix of epoxy and 405 filleting adhesive filler to a

paste where the peaks would not fall off. Slop that into the middle of where

the base will be. I

mixed up a 2 or 3 squirt mix of epoxy and 405 filleting adhesive filler to a

paste where the peaks would not fall off. Slop that into the middle of where

the base will be.

The

trick here is to position the winch correctly. The pencil marks are crucial.

make sure you put enough of a blob down that it fills under the winch base

entirely. Then when everything is positioned just so, take a stirring stick

or your finger and scrap up the excess that spluged out. The

trick here is to position the winch correctly. The pencil marks are crucial.

make sure you put enough of a blob down that it fills under the winch base

entirely. Then when everything is positioned just so, take a stirring stick

or your finger and scrap up the excess that spluged out.

Here

you see the edges filleted nicely, and the base ready to kickoff and harden.

I took a piece of tape from the companionway side to the top of the winch

just to secure it so it doesn't shift down the top of the cabin. Here

you see the edges filleted nicely, and the base ready to kickoff and harden.

I took a piece of tape from the companionway side to the top of the winch

just to secure it so it doesn't shift down the top of the cabin.

Here

is a close up of the sticks and the epoxy fillet. I will clean everything up

and sand the excess epoxy smooth. I will fair out the fillet to blend it

more into the cabin top also. Here

is a close up of the sticks and the epoxy fillet. I will clean everything up

and sand the excess epoxy smooth. I will fair out the fillet to blend it

more into the cabin top also.

.Here

I am building the epoxy base for the starboard winch that will control the

starboard traveller car haul. The winch is a Lewmar single speed #7. .Here

I am building the epoxy base for the starboard winch that will control the

starboard traveller car haul. The winch is a Lewmar single speed #7.

You

can see the angle of the base here. I trimmed off the exposed sticks with a

chisel. You

can see the angle of the base here. I trimmed off the exposed sticks with a

chisel.

I

have added the first application of epoxy thickened in microballs to build a

nice fillet around the base. I

have added the first application of epoxy thickened in microballs to build a

nice fillet around the base.

And

here you can see I have drilled the mounting holes and cut a water drain

groove. The base is ready to paint. And

here you can see I have drilled the mounting holes and cut a water drain

groove. The base is ready to paint.

Installing a Solar Vent in the

Head

This is the second solar vent I am

installing; the other being in the

lazarette hatch. It is a Nicro 2000 Day/Night solar vent, requiring a

4-1/2" hole cut in the cabin top. I

am

locating it forward of the dorade box and as close to the mast step as I can

get. Here is the mark on the cabin. I drilled a 1/4" hole at the mark to

confirm it was located ok inside the head. am

locating it forward of the dorade box and as close to the mast step as I can

get. Here is the mark on the cabin. I drilled a 1/4" hole at the mark to

confirm it was located ok inside the head.

Then

I used the drill bit in the hole to locate the center of a plywood trim ring

I cut that will be used to mount a second deck plate inside the head. I

epoxied the trim ring in place. Then

I used the drill bit in the hole to locate the center of a plywood trim ring

I cut that will be used to mount a second deck plate inside the head. I

epoxied the trim ring in place.

The

I used my monster 1/2 drill and hole saw to cut the hole in the cabin top.

Once again it is The

I used my monster 1/2 drill and hole saw to cut the hole in the cabin top.

Once again it is

very

reassuring to see bone dry balsa coring. I used a narrow chisel to dig out

the balsa from around the edge of the hole, back about 1/2". I thoroughly

wetted the balsa out with very

reassuring to see bone dry balsa coring. I used a narrow chisel to dig out

the balsa from around the edge of the hole, back about 1/2". I thoroughly

wetted the balsa out with

unthickened

epoxy, and used a caulking tube to inject a very thick mixture of epoxy and

404 high density filler into the gap. unthickened

epoxy, and used a caulking tube to inject a very thick mixture of epoxy and

404 high density filler into the gap.

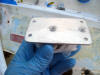

When the epoxy hardened I took a drum

sander on my drill and eased the top

edge

for the deck plate and smoothed the vertical edge of the hole. Here you can

see that the deck plate fits flat against the cabin top in this area. edge

for the deck plate and smoothed the vertical edge of the hole. Here you can

see that the deck plate fits flat against the cabin top in this area.

Then

I test fit the solar vent. The location is ideal for me. I do very little

mast work on the port side of the mast and when I do I can comfortably

position the vent between my feet. Then

I test fit the solar vent. The location is ideal for me. I do very little

mast work on the port side of the mast and when I do I can comfortably

position the vent between my feet. Here is a shot of the vent from inside the head. Still needs some work but I

am waiting on the interior deck plate first before I continue.

Here is a shot of the vent from inside the head. Still needs some work but I

am waiting on the interior deck plate first before I continue.

Mounting the Mainsheet Return

Block

The mainsheet comes off the boom at the

most forward block, and down to a standup block mounted on the mast step. I

call it the mainsheet return block since the sheet makes a turn around it

and leads back to the sheet stopper and winch at the aft end of the cabin.

Mounting the block is straight forward--it is the location where the

original block was, but I relocated it to the end of the mast step so it

makes a fair lead around the aft uprights of the dorade guards when the boom

is all the way eased.

First

I drilled oversized holes, in this case down about an inch to the steel

plate that is First

I drilled oversized holes, in this case down about an inch to the steel

plate that is

part

of the mast step support system. I fill the holes with epoxy thickened with

West System 404 High density Adhesive. part

of the mast step support system. I fill the holes with epoxy thickened with

West System 404 High density Adhesive.

Then, I drilled a 7/32 tapping hole for

the tap thru the metal plate and down about 2 inches. The Garhauer block

accepted #10 screws for mounting,

but

I drilled out the holes to accept 1/4 inch screws instead. I like the extra

beef here. but

I drilled out the holes to accept 1/4 inch screws instead. I like the extra

beef here.

Then

I tapped the holes for 1/4 inch long 1-3/4 inch pan head machine screws. Then

I tapped the holes for 1/4 inch long 1-3/4 inch pan head machine screws.

|